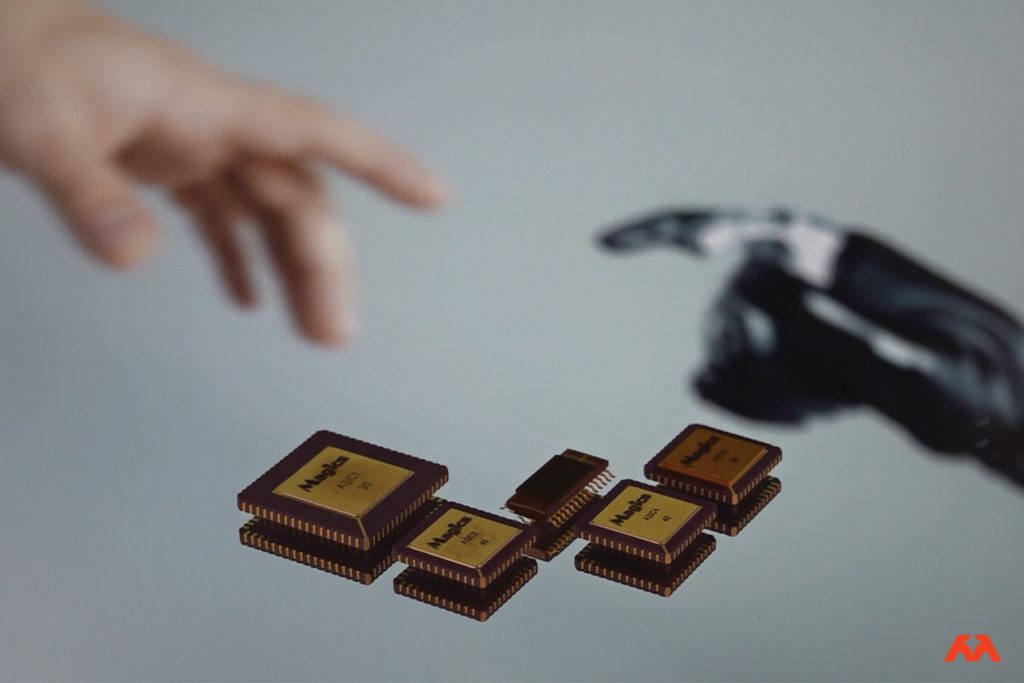

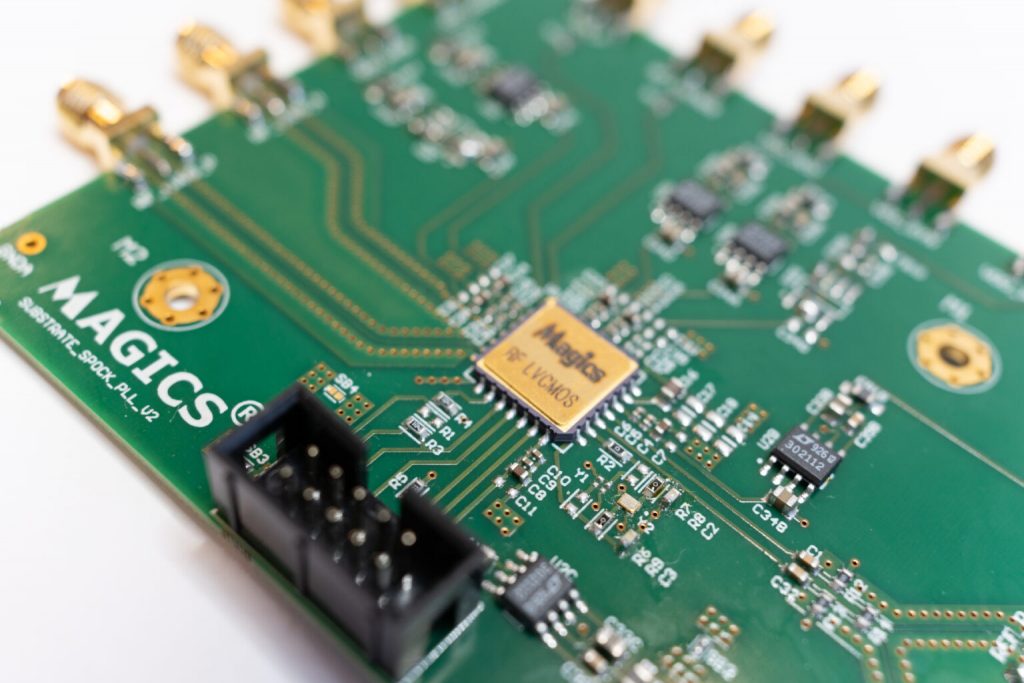

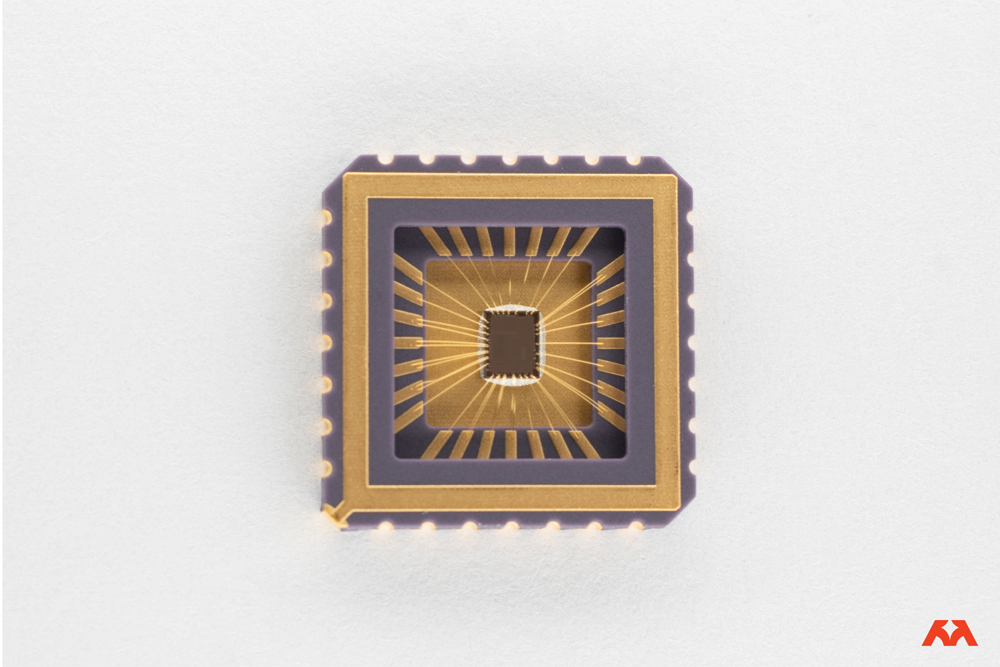

Jens Verbeeck is the CEO and co-founder of Magics Technologies. He graduated as Master in Industrial Sciences, with a focus on electronics in 2007. Jens gained his first professional experience at Intersoft Electronics as electronic hardware engineer. He pursued a PhD degree in Electrical Engineering from the Department of Electrical Engineering (ESAT) of KU Leuven. Based on this research he co-founded together with Ying Cao Magics Technologies, which specialises in the design of semiconductor chips and machine-learning-based smart sensors.